ADAS/SPATZ BLOG

triPLEX 1310 Hartrey (PROJECT UPDATE #10) 07.27.2023

EXTERIOR/INTERIOR are 99.99% complete. LANDSCAPING and pre-occupancy CLEANING start this weekend.

Completion photos and video on the near term horizon.

ANDY

triPLEX 1310 Hartrey (PROJECT UPDATE #9) 06.28.2023

INTERIORS are 99% complete. EXTERIOR is not far behind. SITE finishing starts after the holiday weekend.

One more PROJECT UPDATE to go…

ANDY

(Enjoy the long weekend.)

triPLEX 1310 Hartrey (PROJECT UPDATE #8) 05.17.2023

Interior PAINTING, finished CARPENTRY, CABINETRY, HVAC (ductwork), and ORNAMENTAL IRON (stairs & rails) are in progress. Exterior finishes are also starting up now that we are finally into spring.

Getting there.

ANDY

triPLEX 1310 Hartrey (PROJECT UPDATE #7) 04.03.2023

We are well into interior finishing with INSULATION and DRYWALL having been completed.

Now into Spring & back outside: interior PAINTING, finished CARPENTRY, CABINETRY and ORNAMENTAL IRON (stairs & rails).

ANDY

triPLEX 1310 Hartrey (PROJECT UPDATE #6) 02.14.2023

Got enclosed. MECHANICAL TRADES and inspections leading to INSULATION are finished.

Pre-insulation CARPENTRY completed. WINDOWS and DOORS installed. EIFS SYSTEM also completed until Spring using enclosures. Rough PLUMBING, ELECTRICAL, HVAC, and FIRE SUPPRESSION inspected/passed.

Now & Next: INSULATION followed by DRYWALL.

ANDY

triPLEX 1310 Hartrey (PROJECT UPDATE #5) 12.22.2022

NOW & NEXT...still a bit more CARPENTRY exterior/interior rough framing. WINDOWS are now on site. ROOFING is completed until the exterior skin wraps in Spring 2023. GAS SERVICE has been installed. EIFS SYSTEM exterior waterproofing and finish + rough PLUMBING and ELECTRICAL contractors have started. FIRE SUPPRESSION and HVAC to follow.

We are now enclosed…NICE.

Happy Holidays.

ANDY

triPLEX 1310 Hartrey (PROJECT UPDATE #4) 11.08.2022

NOW & NEXT...more CARPENTRY exterior/interior framing + ROOFING install prior to Winter.

The RACE to enclose continues.

ANDY

triPLEX 1310 Hartrey (PROJECT UPDATE #3) 09.26.2022

Pre-slab CARPENTRY layout for PLUMBING & ELECTRICAL has been completed. Interior CONCRETE slab install and joint scoring…done. CARPENTRY framing is ongoing.

NEXT…more CARPENTRY framing + ROOFING install prior to Winter. The RACE to enclose is on.

ANDY

triPLEX 1310 Hartrey (PROJECT UPDATE #2) 07.28.2022

EXCAVATION/CONCRETE started 06.10.2022. As in deuxPLEX(1) at 2122 Dewey, triPLEX(1) does not have a basement. The first floor is slab on grade. The SEWER/WATER service installation followed the completion of the concrete footing and walls, fitting neatly into the process.

NEXT…pre-slab PLUMBING, ELECTRICAL and HVAC followed by CARPENTRY.

ANDY (Enjoy the photos and videos.)

triPLEX 1310 Hartrey (PROJECT UPDATE #1) 06.07.2022

We are BACK from COVID LOCKDOWN!

and we’re starting another NEW CONSTRUCTION PROJECT.

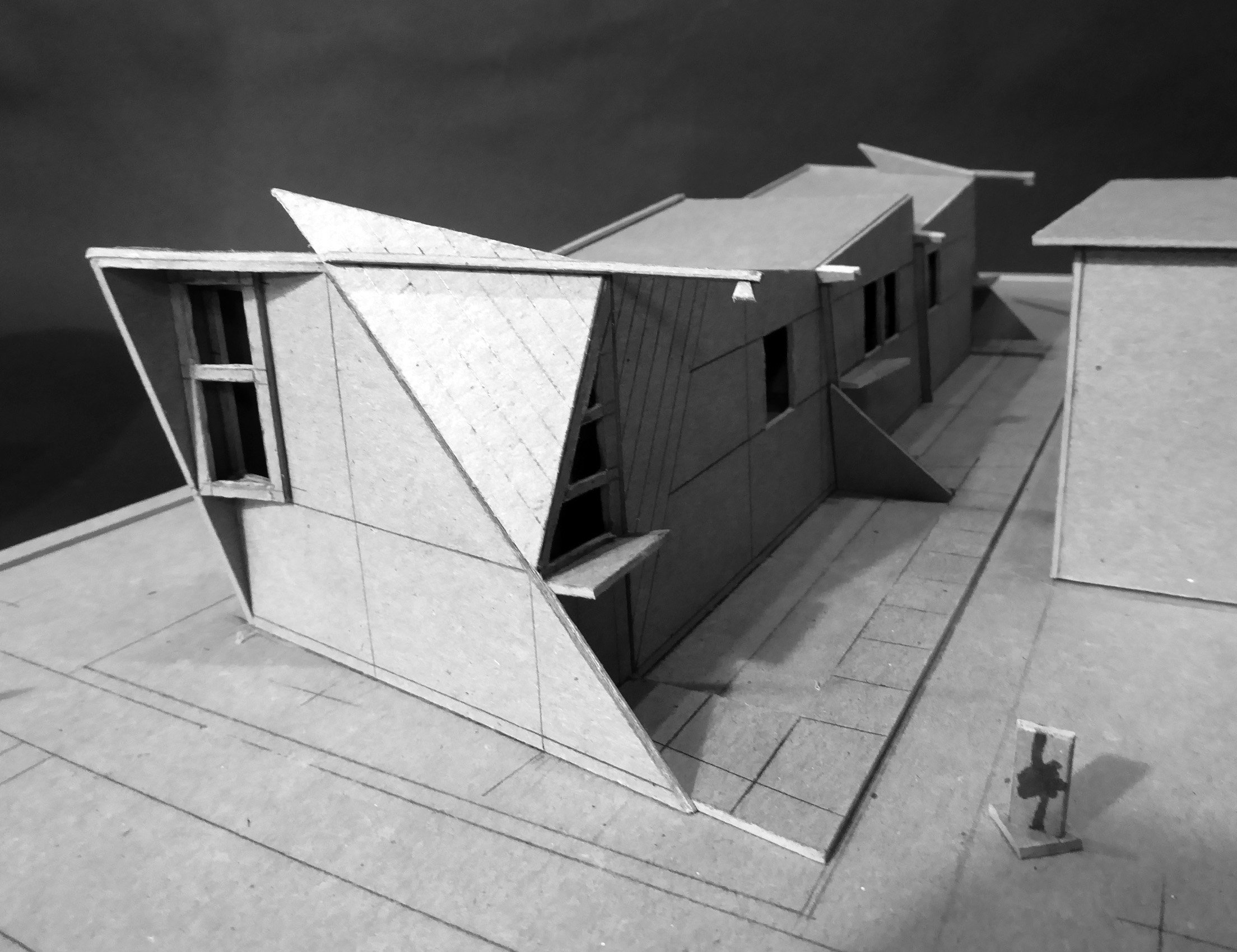

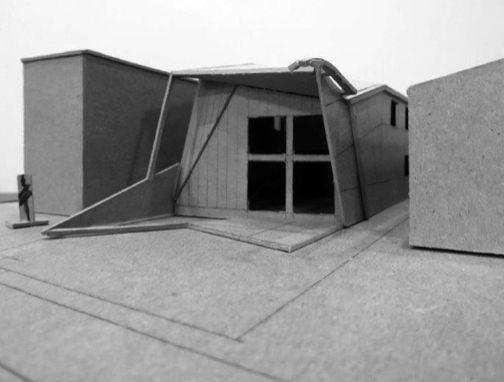

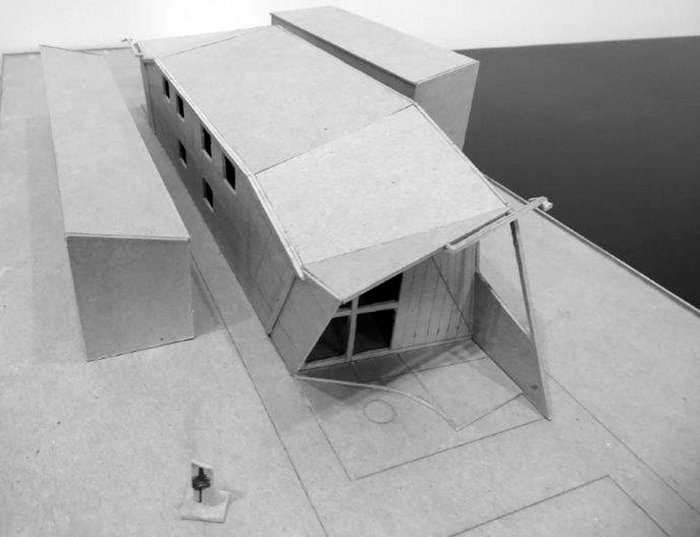

Our goal is to provide a LIVE/WORK unit designed for a post-pandemic world. MORE SPACE, flexibility, and integration of the inside/outside are primary to facilitate a single-family living experience. Evanston zoning allows only 3 units on this 8155 sf parcel. The lot width (48’ total, 28’ buildable) does not allow for adjacent units but rather a back-to-back-to-back, two-level design solution similar to deuxPLEX(1), our last project. This structure will be tightly built, super-insulated, and employ passive house construction techniques. The project will further utilize green-building products including a high-efficiency HVAC system with fresh air intake. The interior space of each unit is approximately 20% larger than older properties in the neighborhood.

We also have 3 other sites, all in Evanston, where we plan on doing similar projects of 2 to 4 units.

Andy

deuxPLEX 2122 Dewey (PROJECT UPDATE) 06.23.2020

MOST IMPORTANT, everyone, please STAY HEALTHY...

During the past 8 weeks we have been busy...the project is nearly finished. Keeping our co-workers SAFE has been a primary and we have all stayed healthy. All trades have completed 99.99% of their interior work with a bit of PAINTING and CARPENTRY remaining. The entire project should be 100% in the next 2-3 weeks.

NOW: CARPENTRY (aluminum soffit panels & standing seam siding) is nearly complete. CONCRETE walks and patios are in process. LANDSCAPING will follow, then a few punch list items to wrap things up.

Enjoy the photos and video.

ANDY

. . .

deuxPLEX 2122 Dewey (PROJECT UPDATE) 04.28.2020

MOST IMPORTANT, everyone, please STAY HEALTHY...

During the past 6 weeks, Matt modified our construction schedule allowing for social distancing and reducing the number of workers on the job which extends the project's completion date. Keeping our co-workers SAFE was the primary, thus we focused on the project's interior. CERAMIC TILE, ORNAMENTAL IRON (steel stairs/rails), PAINTING (prep & 1st finish coat) and CARPENTRY (trim & cabinet install) are near completion.

NOW: At the end of last week, exterior finishes started with CARPENTRY (aluminum soffit panels & standing seam siding). Concurrently, interior PLUMBING (trim), HVAC (furnace install) and ELECTRICAL (fixture trim) started.

Enjoy the photos and videos.

ANDY

. . .

deuxPLEX 2122 Dewey (PROJECT UPDATE) 03.24.2020

A very BELATED posting...

During the past 10 weeks, winter cooperated enough so that the EFIS (synthetic stucco) was completed with only the finished coat remaining. ROOFING work is now 90% completed, making the interior 100% watertight. We are well into the interior finishing stages with INSULATION and DRYWALL having been completed.

NOW: interior PAINTING, finished CARPENTRY, CABINETRY and ORNAMENTAL IRON (stairs & rails)

On this project we will continue with more images and less captions, unless I hear otherwise. Please note, the last photos were taken 2 weeks ago.

We will try to enjoy the mandated SPRING BREAK and stay HEALTHY...you, too.

ANDY

. . .

deuxPLEX 2122 Dewey (PROJECT UPDATE) 01.08.2020

BACK from the HOLIDAYS...

During the past 7 weeks, the CARPENTERS have completed 95% of the interior/exterior framing. Temporary heat has been installed. The INSULATION, PLUMBING, FIRE SUPPRESSION, ELECTRICAL, and HVAC contractors have completed their pre-drywall work and we are ready for building department rough inspections. The weather has been cooperative and the EFIS (synthetic stucco) and ROOFING work is well underway.

NEXT: INSULATION, DRYWALL, and finished CARPENTRY.

On this project, we will continue with more images and less captions unless I hear otherwise.

A belated HAPPY NEW YEAR to you and yours. As usual, Instagram and YouTube links below.

ANDY

. . .

deuxPLEX 2122 Dewey (PROJECT UPDATE) 9.24.2019

Pre-concrete slab PLUMBING, ELECTRICAL and HVAC have been installed. The existing 6” clay sewer piping was re-lined from the parkway to the city sewer line and is a better end product than initially installed. All systems were thoroughly checked and tested prior to the pouring of CONCRETE. NEXT…CARPENTRY rough framing and the first glimpses of the end product.

ANDY (enjoy the photos and video)

. . .

deuxPLEX 2122 Dewey (PROJECT UPDATE) 9.10.2019

We started preparing for demolition on 7/1 with the installation of the construction fence followed by utility disconnections. We removed/recycled anything metallic then demolished and hauled the frame building. Electrical conduit, plumbing pipe and other items were separated and also recycled. This took less than 3 days. Our EXCAVATION/CONCRETE contractor did the DEMOLITION, expediting the process. EXCAVATION/CONCRETE could also be done concurrently. The project does not have a basement. The first floor is slab on grade. Our new SEWER/WATER service and STRUCTURAL STEEL fit neatly into this process.

NEXT…pre-slab PLUMBING, ELECTRICAL and HVAC followed by CARPENTRY.

ANDY (enjoy the photos)

. . .

deuxPLEX 2122 Dewey (PROJECT UPDATE) 7.31.2019

We are BACK!

And this project is NEW CONSTRUCTION.

Our primary goal is to provide the experience of single-family residential living at a cost typically associated with apartment living. The R4 zoning permits only 2 units (2500 FS of lot area/unit) on the 6,116 SF lot. The narrow lot width (36' total, 26' buildable) does not allow for two adjacent units but rather a back-to-back, two-level design solution. This structure will be tightly built, super-insulated and employ passive house construction techniques. The project will utilize green-building products and high-efficiency HVAC and plumbing equipment. The 1,893 SF (no basement) interior space of each unit is approximately 15% larger than older single-unit properties in the neighborhood.

We have 3 other sites, all in Evanston, where we plan on doing similar projects of 2 to 4 units. The exteriors will be much different, but the floor plans will remain the same, for obvious reasons. We also have our eyes on other properties that we can move on at the appropriate time.

Andy

Check out the demolition video!

. . .

wareHOUSE(2) 2113 Greenleaf (PROJECT UPDATE) 6.14.2018

wareHOUSE(2)

2113 GREENLEAF

Evanston, Illinois 60201

adas/spatz properties

PROJECT UPDATE (06.14.2018):

This episode’s focus is exclusively on the EXTERIOR SUN SCREENS and unit entry LOGGIA. These elements are primary to the projects exterior design. The aluminum tube/pipe armature was built in a local shop full size with some dimensions over 70'. Panels were then cut into 3 or 4 pieces, shipped to the job site and then re-assembled prior to erection. Once in place, the armatures are skinned with 1/8" solid and perforated aluminum panels depending on their facade location. All material, transport and labor was locally sourced. Aluminum is made from 90% recycled content and is 100% recyclable, thus is a very green/cost effective/low maintenance material.

Concurrently, multiple trades continue the north to south rotation finishing their portion on the project and will be featured in a future project update shortly.

NEXT, exterior sun screens/unit entry loggia continue, site work + continuation of finishing the interiors.

…the end is near

andy